Specifications

Application

UPEL-P, the chemical protection hose with a black, conductive UPE liner in accordance to EN 12115 and highest safety standards.

Suitable for the transport of acids, alkalis, aqueous solutions of salts, organic compounds (alcohols, esters, ketones, etc.) incl. aromatic substances, chlorinated hydrocarbons and oxidising acids according to our chemical resistance list.

Feature

The Resist U tube has an extremely low friction coefficient and good abrasion resistance.

The used peroxide cured compounds grant excellent temperature resistance and a safe fit to couplings even after several steam cleaning cycles. These new compounds as well the changed helix construction improves significantly the flexibility and reduced bending radius

Standard/Approval

EN 12115:2021, TRbF 131/2:1992.

UPE tube material is in accordance with FDA 21.CFR.177.156.

Temperature range

Tube depending on the flow medium up to +100°C. Hose flexible down to -35°C. Steam cleaning without pressure up to 130°C / max. 30 min.

Safety factor

5 : 1 (exceeds EN12115).

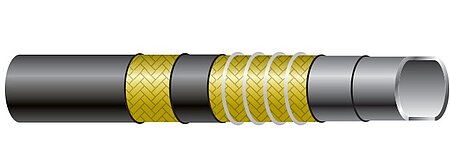

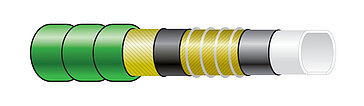

Tube

UPE, black, electrically conductive, smooth.

Reinforcement

Textile braided, zinc plated double steel wire helix.

Cover

EPDM, black, resistant to ozone and weather, abrasion resistant, electrically conductive, cloth impression.

Marking

continuous mylartape, white letters, blue tape: "SEMPERIT (S) RESIST-U Chemie UPEL-P WP 16 bar MADE IN EU //////", as well as continuous embossed tape: "SEMPERIT (S) UPEL-P EN 12115:2021 TRbF 131/2 UPE SD NW.. PN 16 bar Ω/T xQ/YY".

Notice

ATTENTION: The temperature of the medium must be lower than its boiling point.

ATTENTION: Please refer to the Semperit resistance list or, in case of doubt, contact Semperit.

ATTENTION: Continuous use at the peak values reduces the service life.

ATTENTION: To ensure the assembly is leakproof, it must be tested according to EN 12115:2021.

Technical details

| Article number | Internal-Ø | Wall width | External-Ø | Work. pressure (max.) | Number of inserts | Bending radius (min.) | Weight approx. | Coil length (max.) | |

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | bar | mm | kg/m | m | ||

| 48364 1960 | 19.0 | 3/4 | 6.0 | 31.0 | 16 | 2 | 90 | 0.70 | 40 |

| 48364 2560 | 25.0 | 1 | 6.0 | 37.0 | 16 | 2 | 100 | 0.80 | 40 |

| 48364 3260 | 32.0 | 1 1/4 | 6.0 | 44.0 | 16 | 2 | 125 | 1.00 | 40 |

| 48364 3865 | 38.0 | 1 1/2 | 6.5 | 51.0 | 16 | 2 | 150 | 1.30 | 40 |

| 48364 5070 | 50.0 | 8.0 | 66.0 | 16 | 2 | 200 | 1.85 | 40 | |

| 48364 6380 | 63.0 | 2 1/2 | 8.0 | 79.0 | 16 | 2 | 250 | 2.35 | 40 |

| 48364 7575 | 75.0 | 8.0 | 91.0 | 16 | 2 | 300 | 2.60 | 40 | |

Vacuum resistance to -0.9 bar