Specifications

Application

For the use of saturated steam and hot water in the chemical and petrochemical industry, as well as in plant engineering, the construction industry and shipbuilding.

Feature

The DS1 ultra is designed for highest demands in industry. Two braids of zinc-plated steel-wire offer best resistance to superheated steam (up to + 230 ° C) and prevents corrosion.

DS1 ultra is characterized by a high flexibility, small bending radius and small bending force as well.

Electrically conductive: Resistance R<106 Ohm.

Standard/Approval

EN ISO 6134:2017 Type 2, class A.

Temperature range

-40°C / +210°C (saturated steam), peak +230°C (super heated steam); +120°C (hot water).

Safety factor

Steam 10 : 1, Hot water 3,15 : 1

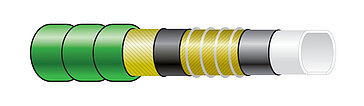

Tube

EPDM, black, electrically conductive, smooth.

Reinforcement

Zinc plated steel braided.

Cover

EPDM, black, resistant to ozone and weather, electrically conductive, cloth impression.

Marking

continuous mylartape, red letters: "SEMPERIT (S) DS 1 ultra Sattdampf / Saturated Steam WP 18 bar 210°C (peak +230°C) R<106 Ohm MADE IN EU //////", as well as continuous embossed tape "SEMPERIT (S) DS1 ultra EN ISO 6134:2017 2A DAMPF / STEAM - PN 18 bar (1,8 MPa) 210 °C (peak 230°C) NW Ω xQ/YY (with EN dimensions).

Notice

ATTENTION: Use only suitable fittings (clamp fittings according to EN 14423:2016).

ATTENTION: Superheated steam shortens considerably the service life of the hose!

ATTENTION: Please refer to our saturated steam table.

Technical details

| Article number | Internal-Ø | Wall width | External-Ø | Work. pressure (max.) | Number of inserts | Bending radius (min.) | Weight approx. | Coil length (max.) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | Satur. steam [bar] | Hot water [bar] | mm | kg/m | m | ||

| 68707 1360 | 13.0 | 1/2 | 6.0 | 25.0 | 18 | 55 | 2 | 65 | 0.55 | 40 |

| 68707 1366 | 13.0 | 1/2 | 6.0 | 25.0 | 18 | 55 | 2 | 65 | 0.55 | 60 |

| 68707 1660 | 16.0 | 5/8 | 6.0 | 28.0* | 18 | 55 | 2 | 75 | 0.60 | 40 |

| 68707 1960 | 19.0 | 3/4 | 6.0 | 31.0* | 18 | 55 | 2 | 90 | 0.70 | 40 |

| 68707 1970 | 19.0 | 3/4 | 7.0 | 33.0 | 18 | 55 | 2 | 90 | 0.85 | 40 |

| 68707 1976 | 19.0 | 3/4 | 7.0 | 33.0 | 18 | 55 | 2 | 90 | 0.85 | 60 |

| 48707 2575 | 25.0 | 1 | 7.5 | 40.0 | 18 | 55 | 2 | 145 | 1.10 | 40 |

| 48707 3280 | 32.0 | 1 1/4 | 8.0 | 48.0 | 18 | 55 | 2 | 200 | 1.55 | 40 |

| 48707 3880 | 38.0 | 1 1/2 | 8.0 | 54.0 | 18 | 55 | 2 | 240 | 1.80 | 40 |

| 48707 5090 | 50.0 | 9.0 | 68.0 | 18 | 55 | 2 | 340 | 2.65 | 40 | |

| 48707 5190 | 50.8 | 2 | 9.0 | 68.8 | 18 | 55 | 2 | 340 | 2.65 | 40 |

Vacuum resistance up to ID 32: - 0.8 bar; up to ID 50: -0.4 bar * No EN ISO 6134:2017 dimension