Specifications

Application

Very robust, compact suction and delivery hose for filling and discharging petrol tankers and rail tank wagons with unleaded fuels (EN 228:2017) with oxygen components limited according to EEC 85/536 and with an aromatic content of 50% max.

Suitable for industrial oils, diesel oils (EN 590:2017), fuel oils (DIN 51 603 parts 1 - 5), mineral oil based hydraulic oils.

Feature

Very robust but also extremely flexible, due to special helix design.

This hose has been tested according to the technical regulations for combustible liquids TRbF 131/2:1992.

Temperature range

-30°C / +90°C.

Safety factor

4 : 1

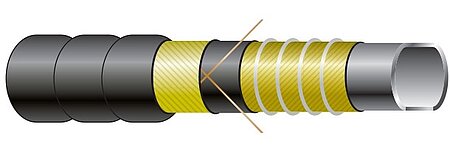

Tube

NBR, black, electrically conductive, smooth.

Reinforcement

Textile wrapped, zinc plated double steel wire helix, copper wire.

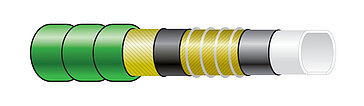

Cover

CR, black, resistant to ozone and weather, abrasion resistant, resistant to oil, electrically conductive, flat corrugated with cloth impression.

Marking

continuous mylartape, yellow letters: "SEMPERIT (S) TMSL Mineralöl/Oil Tankmeister® - superleicht SD PN 10 bar R < 106 Ohm", as well as continuous embossed tape: "SEMPERIT (S) TMSL TRbF 131 / 2 SD NW X PN 10 bar XQ/YY".

Notice

Further development of the TML tanker hose.

Due to the elongation of the special helix design, we recommend maximum pressure of 6 bar be applied, as is normally the case for filling perations.

Technical details

| Article number | Internal-Ø | Wall width | External-Ø | Work. pressure (max.) | Number of inserts | Bending radius (min.) | Weight approx. | Coil length (max.) | |

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | bar | mm | kg/m | m | ||

| 64136 3260 | 32.0 | 1 1/4 | 6.00 | 44.0 | 10 | 2 | 55 | 0.80 | 40 |

| 64136 3865 | 38.0 | 1 1/2 | 6.50 | 51.0 | 10 | 2 | 70 | 1.20 | 40 |

| 64136 5075 | 50.0 | 2 | 7.50 | 65.0 | 10 | 2 | 80 | 1.85 | 40 |

| 64136 6380 | 63.5 | 2 1/2 | 8.00 | 79.5 | 10 | 2 | 90 | 2.05 | 40 |

| 64136 7575 | 75.0 | 3 | 7.50 | 90.0 | 10 | 2 | 100 | 3.00 | 40 |

| 64136 0080 | 100.0 | 4 | 8.00 | 116.0 | 10 | 2 | 150 | 3.50 | 40 |

Vacuum resistance up to -0.9 bar